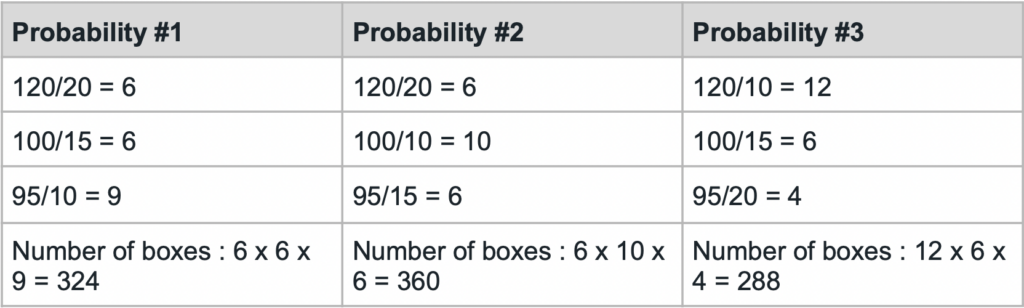

2 packaging types to consider for your needs

While it is true that different businesses have different needs for cardboard packaging products, the same is also true for the various goods that a business offers.

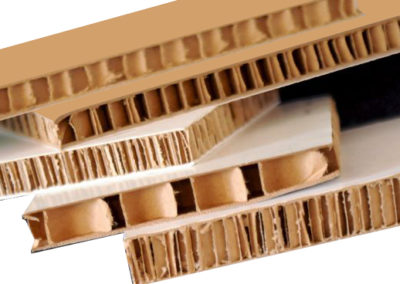

It is necessary to choose the proper cardboard packaging type in order to ensure the safe delivery of goods to their destinations. So here is a brief introduction to two common cardboard box types: honeycomb and corrugated.

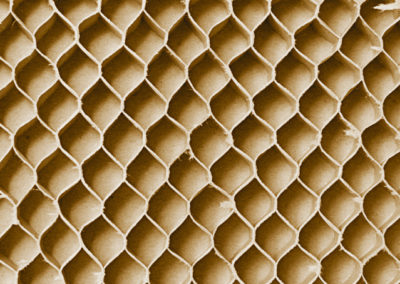

Honeycomb cardboard boxes : a durable type of box

Honeycomb cardboard, known for its exceptional lightness, has numerous alveoli, each of varying sizes. The latter’s presence ensures that this type of cardboard will maintain its well-known high level of resistance ( between 8 and 110 PSI). It is typically advised to choose a thick honeycomb cardboard in order to get the best resistance possible.

By selecting the right type of alveoli, it is possible to create a cardboard that is extremely durable and shock-absorbing without adding any weight. This combines the best aspects of both worlds while guaranteeing lower transportation costs.

To be more precise, the carton is made of thin cardboard sheets that are adhered together and then folded twice to reach the desired height. This ensures that the product is packaged properly. Remember that the height varies from 6 to 150 millimetres.

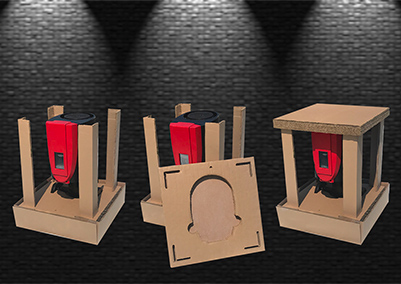

A multipurpose cardboard : corrugated cardboard

Corrugated cardboard is made up of one or more sheets that are themselves adhered to one or more sheets of plain paper. There are several variations of this type of cardboard. Here are the main ones:

- simple side ;

- double side ;

- double spline ;

- triple spline.

The cardboard is passed through a clamp made of two rolls that have been heated and tanned to form a gear, creating the spline that can be seen. The corrugated cardboard can be used to transport both light and heavy items due to its extreme versatility. It also has various heights or amplitude slats depending on the use.

As a result, bulkier, heavier goods are packaged using higher splines (between 4 and 4.8 mm), whereas common goods are packaged using lower amplitude splines (0.5 to 1.6 mm). For your knowledge “micro splines” are the name given to these extremely small amplitude splines.

For example, the corrugated cardboard is used to make isothermal boxes for the delivery of food or pharmaceutical goods. Cross-contamination risk and any potential negative effects are eliminated because these boxes are not intended to be used a second time.

This type of cardboard is recyclable, which helps to further reduce the possibility of cross-contamination. Any bacteria and other microorganisms that might be on its surface are killed by temperature increases that occur during this process. Consequently, this kind of cardboard can be used once more safely after being recycled.