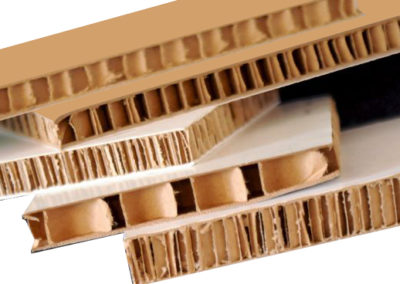

The cardboard is passed through a clamp made of two rolls that have been heated and tanned to form a gear, creating the spline that can be seen. The corrugated cardboard can be used to transport both light and heavy items due to its extreme versatility. It also has various heights or amplitude slats depending on the use.

As a result, bulkier, heavier goods are packaged using higher splines (between 4 and 4.8 mm), whereas common goods are packaged using lower amplitude splines (0.5 to 1.6 mm). For your knowledge “micro splines” are the name given to these extremely small amplitude splines.

For example, the corrugated cardboard is used to make isothermal boxes for the delivery of food or pharmaceutical goods. Cross-contamination risk and any potential negative effects are eliminated because these boxes are not intended to be used a second time.

This type of cardboard is recyclable, which helps to further reduce the possibility of cross-contamination. Any bacteria and other microorganisms that might be on its surface are killed by temperature increases that occur during this process. Consequently, this kind of cardboard can be used once more safely after being recycled.